All Activity

- Yesterday

-

OK, so what i see is you need 1x Result element with this formula and disabled tolerances ( name "ElementResult1" ) It will produce "1" or "0". Now 1x Result element for setting "iO" with this formula ( name "ElementResult-iO" ) Apply this condition Now 1x Result element for setting "NiO" with this formula ( name "ElementResult-NiO" ) And this condition I won't be able to help further - i will be whole week outside Calypso

-

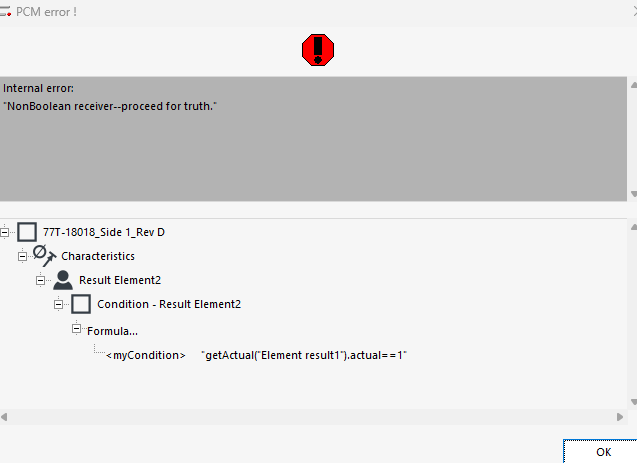

Hi Martin, Thank you for showing me this. Can you help clarify it a bit further. This will display an iO and niO in the name of the pdf generated correct?, Also, this showed up when I try running the program.

-

[YU...] joined the community

[YU...] joined the community -

[Qu...] started following Creating a Passed/Failed reporting folders and PDF-Protokollausgabe, Trennung von i.O- und n.i.O-Protokollen

-

This is doable without PCM. Search forum for "N.i.o." It's only in default names of protocols ( and other files ) Found this:

-

Guten Tag Ich habe bei einem Taster festgestellt das dieser durch das Scanning abgeschliffen ist. Das Problem, erkannt habe ich das erst nach Maßproblemen am Bauteil und als ich den Taster optisch betrachtet habe. Bei der Kalibrierung werden Sigma Werte von 0,0007 ermittelt, weshalb der Taster als i.O. bewertet wird, im Test mit Tensor und Dynamischen Tensor eingemessen. Auf unserem Konturenmessgerät habe ich den Taster abgefahren und festgestellt das mittlerweile 0,014mm abgeschliffen wurden. Warum ist der Sigma Wert immer noch so gering? Bisher konnte ich mich immer darauf verlassen durch den Sigma Wert zu bewerten ob der Taster iO oder NiO ist, als Grenze haben wir uns 0,0010mm gesetzt. Ich habe dann noch eine Vergleichsmessung auf einem Endmaß gemacht, immer der gleiche Antastpunkt je 3x mit unterschiedlichen eingemessenen Tastersystemen und nur der defekte reist aus. Mache ich in der Bewertung nur auf Grund des Sigma Wertes etwas falsch? Bilder sind angehängt. Defekter Taster aber Sigma beim einmessen i.O.pdf

- Last week

-

For future reference my friend. How to Take Screenshots on Windows 11 | Microsoft Windows

-

Hello everyone, Im trying to create a system where reports will be sorted into Passed(no OOT measurement) and Failed( 1 or more OOT measurement). This then will dictate where the report will be save into 2 separate folders. Based on what I research online, it seems doable. I think it might require PCM (I am planning to purchase) and maybe Piweb enterprise. The goal is to be able to sort through the data quickly or even import it directly into a report. If anyone have an idea please help me out. Thank you!

-

[Jo...] joined the community

[Jo...] joined the community -

[Gu...] joined the community

[Gu...] joined the community -

-

Using Length as you marked will move nominals in direction of nominal vectors - aka make diameter bigger/smaller. To move curve along X,Y,Z it's on another tab "Coordinate axes direction". If you are lucky and it's only translation in one axis, then it's safe. Otherwise i would preffer copying this curve, changing it's alignment to have origin and vector from original circle, and just translate. Another option would be making alternative circle, it's strategy and making new curve from this circle's strategy.

-

Determined from will be reported value from calculated shape. That's why you can have measured points or cad entity. Measuring MAX from measured point can have different value than from CAD. Example: measured point is not exactly at -X ( like 10° ). CAD will report max point from calculated circle. Also why is this topic called "Cartesian distance" while this is calliper distance?

-

If you are comparing actuals, don't forget to make correct evaluation of alignment. Datums have to be tangential element and as i saw at Inspect also perpendicular. You have probably made evaluation as Geometry instead of ISO/ASME

-

Is the geometry a cone, or similar? You want to scan two circles and different depths? Did you slice through the model to create the curve? I'm asking these questions to make sure I understand exactly what you want. Slice the model at the called-out depths, creating two curve segments. If the surface is tapered, you might want to use 3d curve.

-

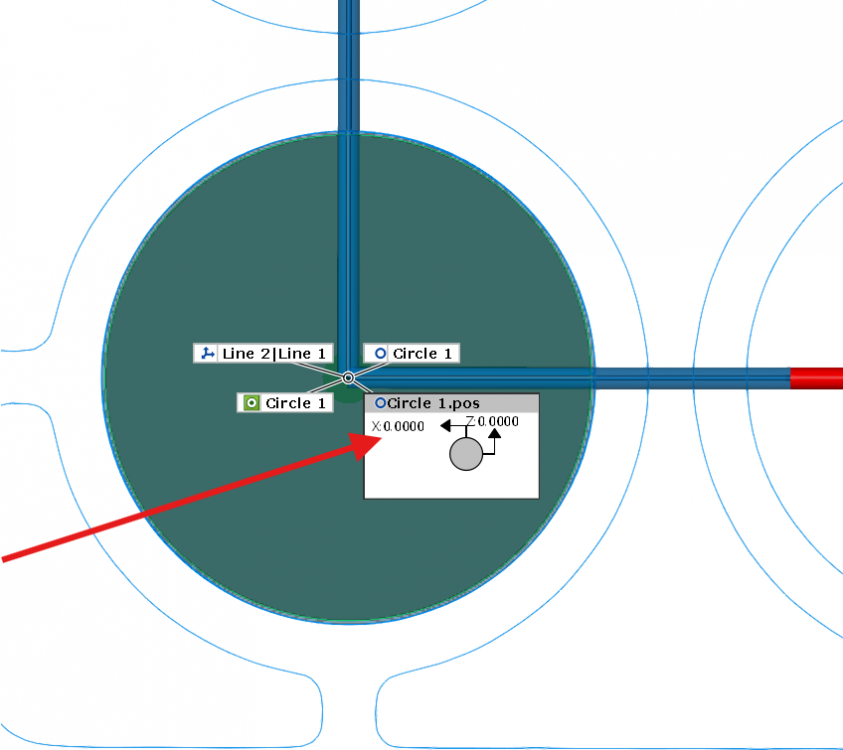

The hole measurement on feature circle20 x-axis is different than when it's being evaluated for position. I can height gauge it on surface plate and get similar value to 46.32 but there is no way for me to replicate 46.52.

-

The "between" section is at what spot on the feature the caliper distance would choose to measure from. "Maximum" would be the farthest points, "Minimum" would be the closest, and "Center" would be the center of the plane. This is more easily described by using a circle instead of planes, if you used 'Minimum" between 2 circles it would measure from the closest section of the circle along its diameter instead of the center of the circle. Maximum would be the parts of the circle farthest away from eachother, and center would be measured from the centerpoint of each circle. If you replaced the planes with circles it would also show in the cad model where exactly from the circle it is measuring so you can mess around with the settings until you understand. If you have more questions let me know Also, I dont know about the "Determined from" section either, so hopefully someone else here can help out with that part

-

In "between" what is the min, max, and center adjusting? In "determined by" on Center, why is 'CAD Entities' the only choice in the drop-down menu? When center is chosen it displays closest to a measurement done with a micrometer.

-

I have a 2D curve from a finished part CAD model, that is a closed end "circle". I need to check this curve on a part with a taper, 2 different heights and different "diameter". Do I go: 2D Curve Nominal Data - Modify Nominals - Nominal Geometry Manipulation - Modify Nominal - Translation - Length and enter the amount to change the size?

-

[St...] joined the community

[St...] joined the community -

PCM script on how to palletize with multiple barcode scan

[is...] replied to [is...] 's topic in PCM

Or each scan will be saved into a user-variable inside the program? -

First off, I am self-learning pcm along the way. I have a full program that you can select to check each process operations up to full customer print by using setRunID(). The first inspector interaction is the selection of operation and then reason for inspection from the dropdown lists. The next Inspector interaction is scanning the barcode once, all information like machine no, fixture no, sequence no. etc, were extracted from the barcode and were used in the program. This program runs with no issues. Help is badly needed with the script on how to perform the task below, paging pcm guru’s here, please and thank you. I need to check 2 workpieces in one run. Palletize – 2 pallet location, which I am already familiar with. The issue which I cannot get around my head is… I need to scan the two (2) workpieces at most in a single program run. How to get the scanned barcodes assigned to respective pallet locations? And what if only one workpiece needs to be checked? The barcode contains the machine and fixture numbers. If 2 pallet locations were used, it would need to be scanned 2 times, if only one pallet location is used, only one scan is needed. That means the number of pallet location activated determines the number of scans. I am thinking that the barcodes needed to be saved somewhere then read and used in the program, then will delete the barcode data/file when the program ends to have a empty data/file for the next run. I am not familiar with how to execute this. Any workflow/pcm codes suggestions for this to work is highly appreciated. The idea is, the inspector will always put fixture 1 in pallet location 1 and pallet location 2 for fixture 2 regardless of machine number. Ex. Machine A – Fixture 1 - assigned to pallet location 1 Machine A – Fixture 2 - assigned to pallet location 2 Machine B – Fixture 1 - assigned to pallet location 1 Machine B – Fixture 2 - assigned to pallet location 2 Thank you in advance and your help is highly appreciated.

-

[Da...] joined the community

[Da...] joined the community -

-

Hey David, unfortunately I don't have a Ø8 mm sphere at the moment.

-

[Ro...] joined the community

[Ro...] joined the community -

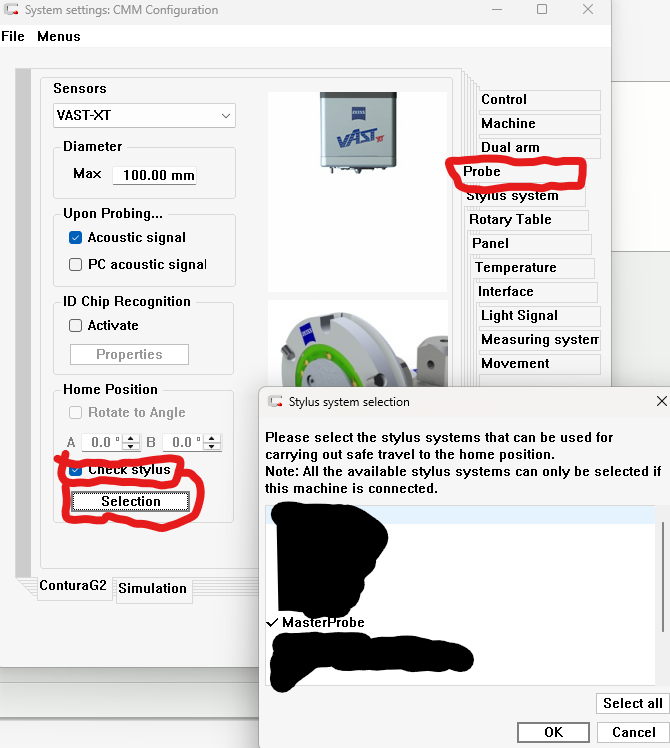

I had to edit a program. New rev, models, dimensions. So, I took it off the live machine and transferred it to my planner. I finished the edits, but to run it in simulation I needed to assign stylus. The only one I have on my planner is different from what the program uses on the machine. They do show up in red as (what I call) ghost styli. Is there any way to retrieve these offline rather than re-assigning them on the live machine?

-

[Fa...] joined the community

[Fa...] joined the community -

System Shut down best practices - leaving a stylus system in the head

[Lu...] replied to [Jo...] 's topic in General

-

I actually got it to work... sort of.... I created my PCM variable, did all my editing inside PCM then used a setRecordHead() variable to my variable. Used a single text box with the header data variable i created and it appears on the report. I get an error message now in calypso before i click on anything (not just inside a program)...see attached... and when i run a program. this is not just in CALYPSO 2025 but also in 2020. The variable reads correctly and is setup, but as soon as I set it to a header variable, after the 1st run, it gives me the error.... for every single line of the variable.

-

[ME...] joined the community

[ME...] joined the community -

[Io...] joined the community

[Io...] joined the community -

[Ro...] started following Evaluation of K Diagram in GearPro Ver7.2 and ACIS Socket Already in Use with Gear Pro 2024 and Calypso 2023

-

ACIS Socket Already in Use with Gear Pro 2024 and Calypso 2023

[Ro...] replied to [Da...] 's topic in ZEISS GEAR PRO

Gentlemen, which colors have the ports in the setup dialog? Can you please provide the zipped logging folder after you activate the yellow marked items and after you get the error message? Please provide this via you local GEAR PRO support team. Thank you. -

[Od...] joined the community

[Od...] joined the community -

Hi. The change of the main evaluation ranges will not effect the K-chart or the K-value. The change will effect all standardized characteristics like Fa, ffa, fHa, ... If you want to create the behaviour you describe, you have to shorten the K-diagram like in the attached screenshot (marked red). I checked also the behavior to deactivate the "tolerance evaluation" of the K-value but the K-values still appear. This seems to be a bug. I assigned this issue directly to our development team. For such cases it would be really helpful to get your measurement file .act directly through your local support team in our organization. If this happens we can document the bug and from which version on it is corrected. May I kindly ask you to provide your measurement file .act to our support team. Inform them to link the .act to issue no. 819665. Thank you.

-

I report the measurement duration on my piweb report, i wasnt able to find it in the variable drop down menus, but looking at the text for the measurement duration it shows exactly the same as Martin Jansky listed. For me it reports the same time displayed in Calypso Monitor, no PCM needed here it is in piweb designer and here it is in the actual report piweb generates

.png.109560dc7c2015fdad983c5f747fcdfa.png)